3D Print Services

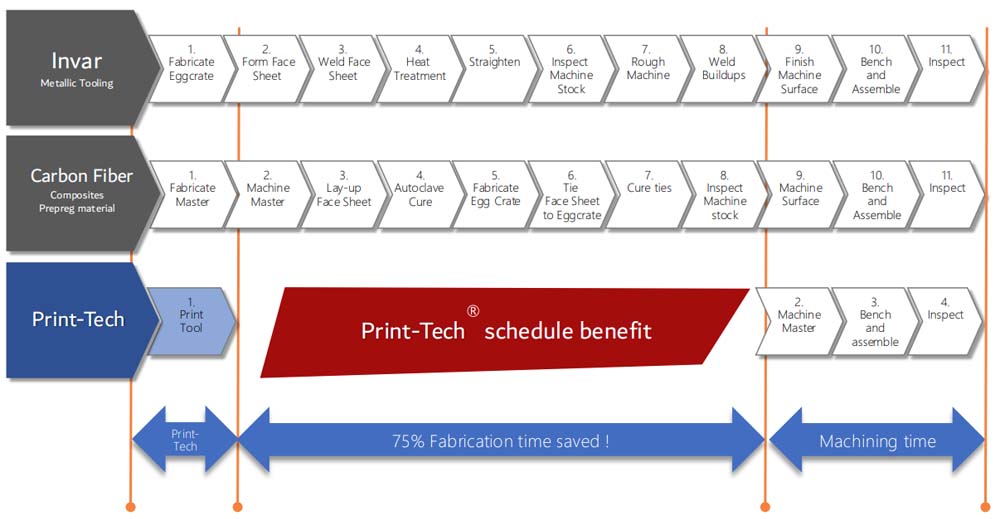

Shorter Lead Time

- Print-Tech® builds 3D near net shape tooling faster than any other process

- Face Skin & sub-structures simultaneously fabricated at high deposition rates

- New program & prototyping schedule friendly, for faster time to part

Cost Benefits

- Reduction in program complexity, risk of delay, and associated mitigation of costs

- Large reduction in material waste through traditional subtractive manufacturing supply chain

- Reduced total cost of manufacture compared to conventional tooling

- Dahltram® materials developed for Low Cost, application matched performance

Scale Benefits

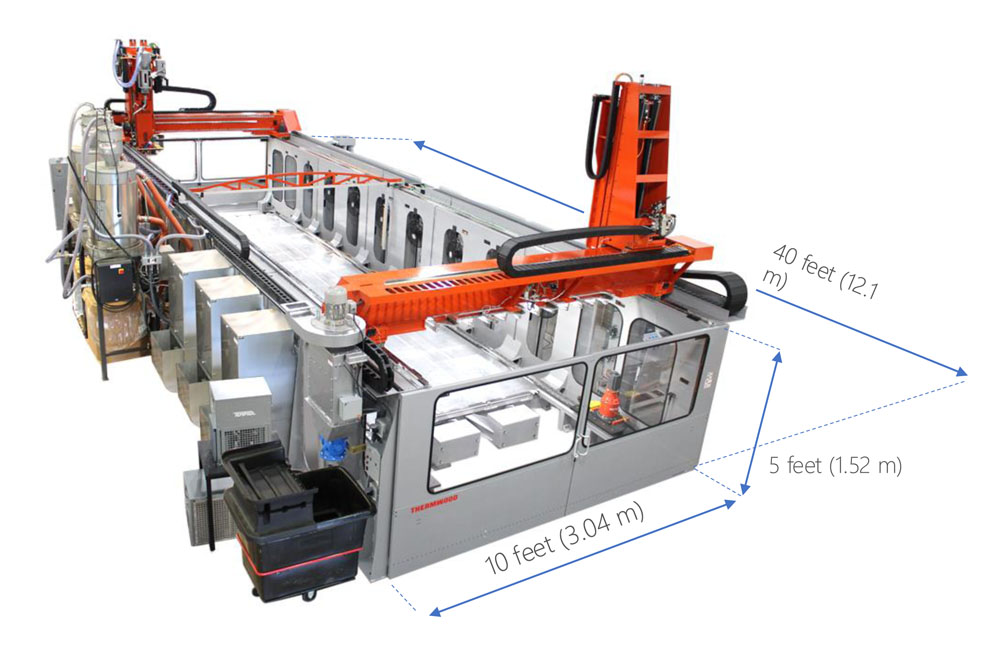

- Largest available tool print ready LSAM

- Large reduction in material waste through traditional subtractive manufacturing supply chain

- Reduced total cost of manufacture compared to conventional tooling

- Dahltram® materials developed for low cost, application matched performance

- Large 10’ x 40’ x 5’ (3 x 12 x 1,5m) build volume

- Additive / Subtractive build

- High deposition rates

- High accuracy machining