Filament - Kimya

Kimya 3D Filaments by Airtech supports you and your projects with advanced materials for additive manufacturing. Our solutions are for those who wish to integrate additive manufacturing into their production processes for finished parts, tooling or quick prototyping.

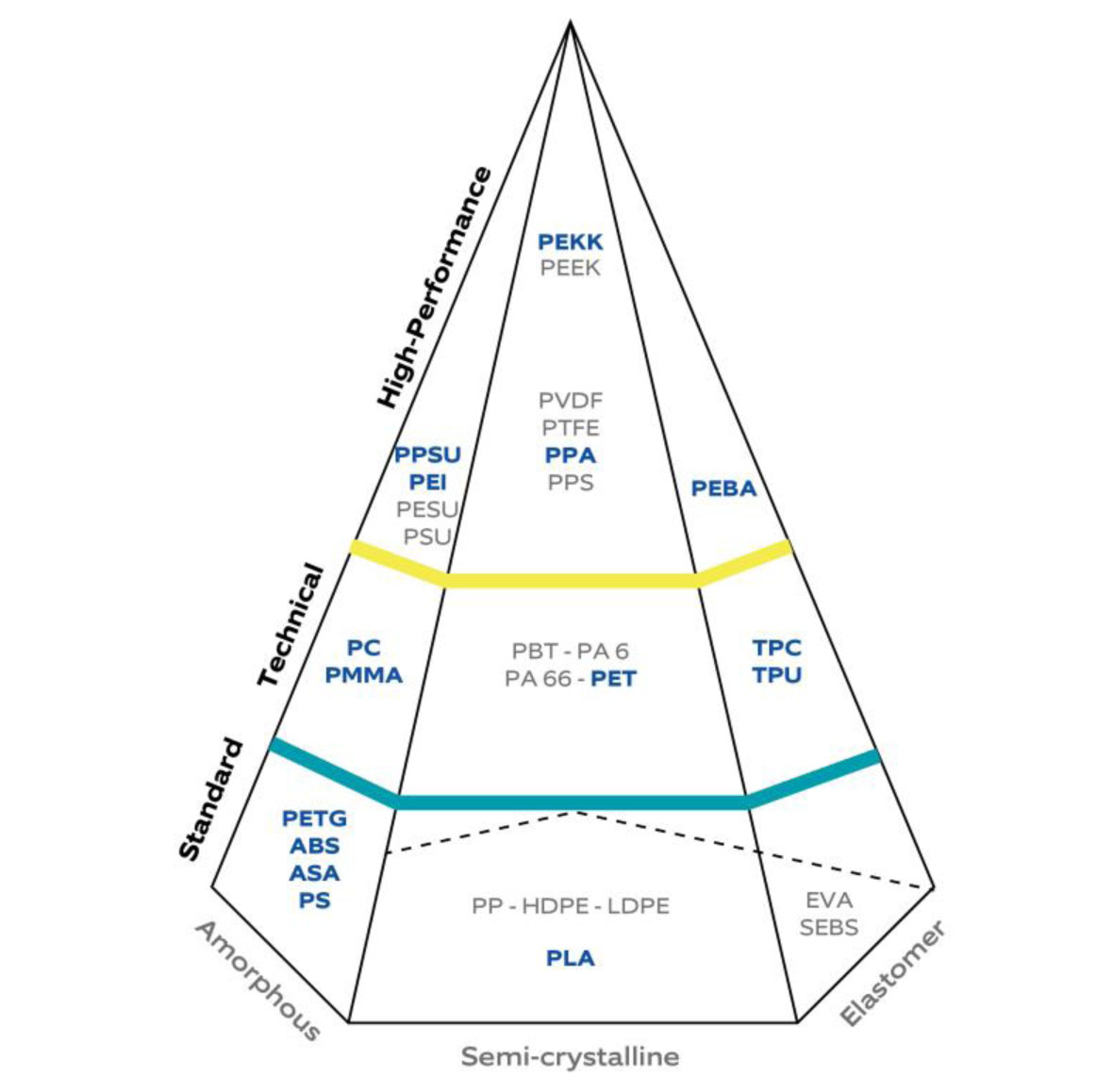

Thanks to our expertise in the field of additive manufacturing, we have developed a vast range of 3D filaments enabling you to design all your projects in an instant. The Kimya product line offers numerous 3D filament spools: ABS, ASA, HIPS, PEI, PEKK, Polycarbonate, Flexible, PPSU, PET, PLA…Every filament has been subjected to rigorous formulation, analysis and characterization conducted by the experts in the lab. All the filaments have been tested and verified via a battery of printing simulations for different applications. A number of our materials have been designed and certified to provide resistance against high temperatures and solvents. Others can be used in food contact situations or in outdoor conditions. Every 3D filament has its own unique chemical and mechanical properties. Our team of sales and application specialists be glad to help you select the Kimya filament best able to meet your needs.

| BASICS | |

|---|---|

| ABS-S | PETG-S |

| ASA-S | PLA-HI |

| REMAKE | |

|---|---|

| PLA-R | TPU-R |

| PETG-R | HIPS-R |

| ABS-R | PEI-R |

| PA-R | PEKK-R |

| FLEXIBLE | |

|---|---|

| TPC-ESD | TPU-92A |

| PEBA-S | TPC-91A |

| TECHNICALS | |

|---|---|

| ABS Carbon | PETG Carbon |

| ABS Kevlar | PA6-CO |

| ABS-ESD | ABS-EC |

| PA11 | ABS-EC |

| ULTRAS | |

|---|---|

| PEKK-A | PEI-1010 |

| PEKK-SC | PPSU |

| PEI-9085 | PEKK Carbon |

| PC-S | PC-FR |

| Support HT | |

| Dahltram | |

|---|---|

| rPETG-GF | rPETG-CF |

| PC-GF | PC-CF |

| PESU-CF | |

Kimya, embedding Additive into Manufacturing. A solution for manufacturers who wish to integrate additive manufacturing into their production processes for finished parts, tooling or quick prototyping. Kimya 3D Filaments by Airtech supports you in your R&D projects about materials for additive manufacturing.

The Kimya product line offers for sale numerous 3D filament spools: ABS, ASA, HIPS, PEI, PEKK, Polycarbonate, Flexible, PPSU, PET, PLA… Every 3D filament has its own unique chemical and mechanical properties. Contact us and we will help you select the Kimya filament best able to meet your needs. Find your ideal filament!

Thanks to our expertise in the field of additive manufacturing, we have developed a vast range of 3D filaments enabling you to design all your projects in an instant. Every filament has been subjected to rigorous formulation, analysis and characterization conducted by the experts in the lab. All the filaments in have been tested and verified via a battery of printing simulations for different applications. A number of our materials have been designed and certified to provide resistance against high temperatures and solvents. Others can be used in food contact situations or in outdoor conditions.

All our 3D filaments are accompanied by a detailed data sheet to help you make the right choices for your project and your specific printing and utilization constraints. We develop precise printing profiles to guarantee you the best possible result when developing your 3D parts in-house. However, our teams are also at your service to provide you with any advice you might need and to guide you towards the filament spools best suited to your application. Take advantage of their experience and recognized know-how in hi-tech additive manufacturing to achieve your best projects!

We are committed to satisfying our customers by delivering the right solutions and services for their needs. Our products and services improve with every new project and partnership!

| Materials | Properties | Highlights | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| ABS-R |

|

|

|

|

|

|

Post-consumer recycled ABS with properties similar to a standard ABS filament. |

| HIPS-R |

|

|

|

|

|

|

Multipurpose use: 3D printing material and standard breakaway (or soluble) support material compatible with ABS, ASA, PETG, TPU, TPC. |

| PETG-R |

|

|

|

|

|

|

Perfect balance of mechanical properties and flexibility on open chamber printer. Carbon footprint reduced by 30% compared to PETG-S. |

| PLA-R |

|

|

|

|

|

|

Recycled content PLA with high performance. |

| TPU-R |

|

|

|

|

|

|

Flexible material with high impact and abrasion resistance. Resistant to oil and grease. |

| Materials | Properties | Highlights | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| ASA-S |

|

|

|

|

|

|

High impact resistance combined with weather and UV resistance |

| ABS S |

|

|

|

|

|

|

Versatile, tough material. High impact ABS - tougher and higher heat resistance than ASA-S |

| PETG-S |

|

|

|

|

|

|

Excellent standard material. Perfect balance of mechanical properties and flexibility on open chamber printer. |

| Tough PLA-HI |

|

|

|

|

|

|

Tough PLA. Impact resistance mutiplied by 5 compared to standard PLA |

| Materials | Properties | Highlights | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| PEBA-S |

|

|

|

|

|

|

Lightness, superior energy return, impact resistance, extreme elasticity and behavior even at cold temperatures. Soft touch. Good layer adhesion. |

| TPC-91A |

|

|

|

|

|

|

Excellent elasticity in harsh environment. Wide range of chemical resistance. Easier to print than TPU on Bowden printers. Soft touch. Good layer adhesion |

| TPC-ESD |

|

|

|

|

|

|

Good elasticity combined with electrostatic discharge safety (ESD). Soft touch. Good layer adhesion. |

| TPU-92A |

|

|

|

|

|

|

Flexible. Higher resistance to oils and greases than TPC. Soft touch. Good layer adhesion. |

| Materials | Properties | Highlights | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| ABS CARBON |

|

|

|

|

|

|

Strong, stiff material. Smooth surface aspect. No shrinkage, less warpage and better tensile modulus than ABS-S |

| ABS-EC |

|

|

|

|

|

|

ABS with < 10^6 Ohms surface resistivity |

| ABS ESD |

|

|

|

|

|

|

ESD safe ABS with 10^6 - 10^9 Ohms surface resistivity. |

| PA6-CO |

|

|

|

|

|

|

Easy to use low-warping nylon that combines strength, wear resistance and toughness. |

| PETG CARBON |

|

|

|

|

|

|

Excellent balance between ease to print and strong mechanical properties (rigidity), producing clean finish printed parts. |

| PA-CF |

|

|

|

|

|

|

Exceptional mechanical properties, temperature, and chemical resistance. Recommended for high strength applications in elevated heat environments. |

| Materials | Properties | Highlights | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| PC-FR |

|

|

|

|

|

|

Flame retardant PC. Good dimensional stabililty and wide temperature range |

| PC-S |

|

|

|

|

|

|

Industrial material with superior heat resistance and mechanical properties. Anti-UV reinforced. Sterilizable. |

| PEKK-A KEPSTAN© |

|

|

|

|

|

|

Easy to print ultra with high heat and chemical resistance. |

| PEKK-SC CARBON |

|

|

|

|

|

|

Excellent mechanical properties |

| PEKK-SC KEPSTAN© |

|

|

|

|

|

|

Semi crystalline structure - excellent technical properties all round. Excellent chemical and heat resistance. Ideal for oil & gas applications. |

| PEI1010 ULTEM© |

|

|

|

|

|

|

High rigidity. UV and chemical resistance. High temperature resistance. Gamma radiation resistant |

| PEI-9085 ULTEM© |

|

|

|

|

|

|

Flame retardant. High rigidity. |

| PPSU RADEL© |

|

|

|

|

|

|

Gamma radiation resistant. Sterilizable. Autoclavable. Radiotranslucent Hydrolysis and steam resistance. |

| PEI Support |

|

|

|

|

|

|

Breakaway support, non need of solvent. High temperature resistant. Ideal for use with Kimya PEI-9085 and Kimya PEI-1010, based on ULTEM™ |

| Materials | Properties | Features and Benefits | |||||

|---|---|---|---|---|---|---|---|

| Easy to Print | Rigidity | Flexibility | Impact Resistance | Weather Resistance | Temperature Resistance | ||

| rPETG-GF |

|

|

|

|

|

|

Recycled copolyester with fiberglass reinforcement for enhanced mechanical performance and excellent impact properties. Easy to process with low warpage. |

| rPETG-CF |

|

|

|

|

|

|

Recycled copolyester with fiberglass reinforcement for enhanced mechanical performance and maximum stiffness. Easy to process with low warpage. |

| PC-GF |

|

|

|

|

|

|

Glass reinforced for enhanced mechanical performance with excellent impact properties. Excellent thermal performance and ideal for industrial and engineering grade projects. |

| PC-CF |

|

|

|

|

|

|

Carbon fiber reinforced for high performance with excellent thermal and mechanical properties. Superior print stability and ideal for industrial and engineering grade projects. |

| PESU-CF |

|

|

|

|

|

|

Carbon fibre reinforced for maximum performance with excellent thermal and mechanical properties. Superior print stability and ideal for industrial and engineering grade projects. |