Tooling and Molds

Dahltram®-150CF

| Materials Type | Material Format | Heat Distortion Temperature | Service Temperature |

|---|---|---|---|

| Modified ABS / Carbon Fiber | Pellet | 101°C (214°F) | 88°C (190°F) |

Description

Dahltram® S-150CF is a cost effective, low temperature use, additive manufacturing polymer with a service temperature of 88°C (190°F). It is reinforced with carbon fiber for maximum strength and long-term performance. Dahltram® S-150CF is ideal for room temperature tooling solutions. Additionally, it is vacuum tight and can machined to the tolerances and surface finish required.

Tooling applications

Dahltram® S-150CF is a cost-effective solution ideal for rapid prototyping, trim tools, holding fixtures, inspection fixtures, low temp masters, and much more. Additive manufactured tools can go from conception to the production floor in days not weeks. Easy to process and proven on a range of 3D Printer platforms.

Dahltram® C-250CF

| Materials Type | Material Format | Heat Distortion Temperature | Service Temperature |

|---|---|---|---|

| Modified PC / Carbon Fiber | Pellet / Filament | 1144°C (291°F) | 135°C (280°F) |

Description

Dahltram® C-250CF is a cost effective, low to medium temperature use, additive manufacturing polymer with a service temperature of 135°C (280°F). It is reinforced with carbon fiber for maximum strength and long-term performance. Dahltram® C250CF is ideal for low to medium temperature tooling solutions. Additionally, it is vacuum tight and autoclave capable in all forms and can be machined to the tolerances and surface finish required.

Tooling applications

Provides higher strength, higher temperature performance and higher throughput. Dahltram® C-250CF is a cost effective choice for mould tools working with 121°C (250°F) cure systems. It can also be used for Master models, bonding fixtures and tooling applications where additional strength and temperature resistance is required.

Dahltram® C-250CF is easy to process and proven on a range of 3D Printer platforms.

Dahltram® C-250GF

| Materials Type | Material Format | Heat Distortion Temperature | Service Temperature |

|---|---|---|---|

| Modified PC / Glass Fiber | Pellet / Filament | 144°C (291°F) | 135°C (280°F) |

Description

Dahltram® C-250GF is a cost effective, low to medium temperature use, additive manufacturing polymer with a service temperature of 135°C (280°F). It is reinforced with glass fiber for maximum strength and long-term performance. Dahltram® C250GF is ideal for room temperature tooling solutions, stretch forming and low temperature master moulds. Additionally, it is vacuum tight and autoclave capable in all forms and can be machined to the tolerances and surface finish required.

Tooling applications

Provides higher strength, higher temperature performance and higher throughput. Dahltram® C-250GF is a cost-effective choice for mould tools working with 121°C (250°F) cure systems. It can also be used for Master models, bonding fixtures and tooling applications where additional strength and temperature resistance is required.

Dahltram® C-250GF is easy to process and proven on a range of 3D Printer platforms.

Dahltram® I-350CF

| Materials Type | Material Format | Heat Distortion Temperature | Service Temperature |

|---|---|---|---|

| Modified PEI / Carbon Fiber | Pellet | 212°C (414°F) | 204°C (400°F) |

Description

Dahltram® I-350CF is a cost effective, high temperature use, additive manufacturing polymer with a maximum recommended use temperature of 204°C (400°F). It is reinforced with carbon fiber for maximum strength and long term performance. Dahltram® I-350CF is ideal for high temperature tooling solutions and high temperature master molds. Additionally, it is vacuum tight, autoclave capable, and can be machined to the tolerances and surface finish required.

Tooling applications

Dahltram® I-350CF is a cost effective tooling solution ideal for all types of mould tooling operating with 176°C (350°F) cure systems. Additive manufactured tools can go from conception to the production floor in days not weeks.

Dahltram® I-350CF is easy to process and proven on a range of 3D Printer platforms.

Dahltram® U-350CF

| Materials Type | Material Format | Heat Distortion Temperature | Service Temperature |

|---|---|---|---|

| Modified PESU / Carbon Fiber | Pellet / Filament | 215°C (420°F) | 204°C (400°F) |

Description

Dahltram® U-350CF is a cost effective, high temperature use, additive manufacturing polymer with a maximum recommended use temperature of 204°C (400°F). It is reinforced with carbon fibre for maximum strength and long term performance. Dahltram® U-350CF is ideal for high temperature tooling solutions and high temperature master moulds.

Additionally, it is vacuum tight, autoclave capable, and can be machined to the tolerances and surface finish required.

Tooling applications

Dahltram® U-350CF is a cost effective tooling solution ideal for all types of mould tooling operating with 176°C (350°F) cure systems. Additive manufactured tools can go from conception to the production floor in days not weeks.

Dahltram® U-350CF is easy to process and proven on a range of 3D Printer platforms.

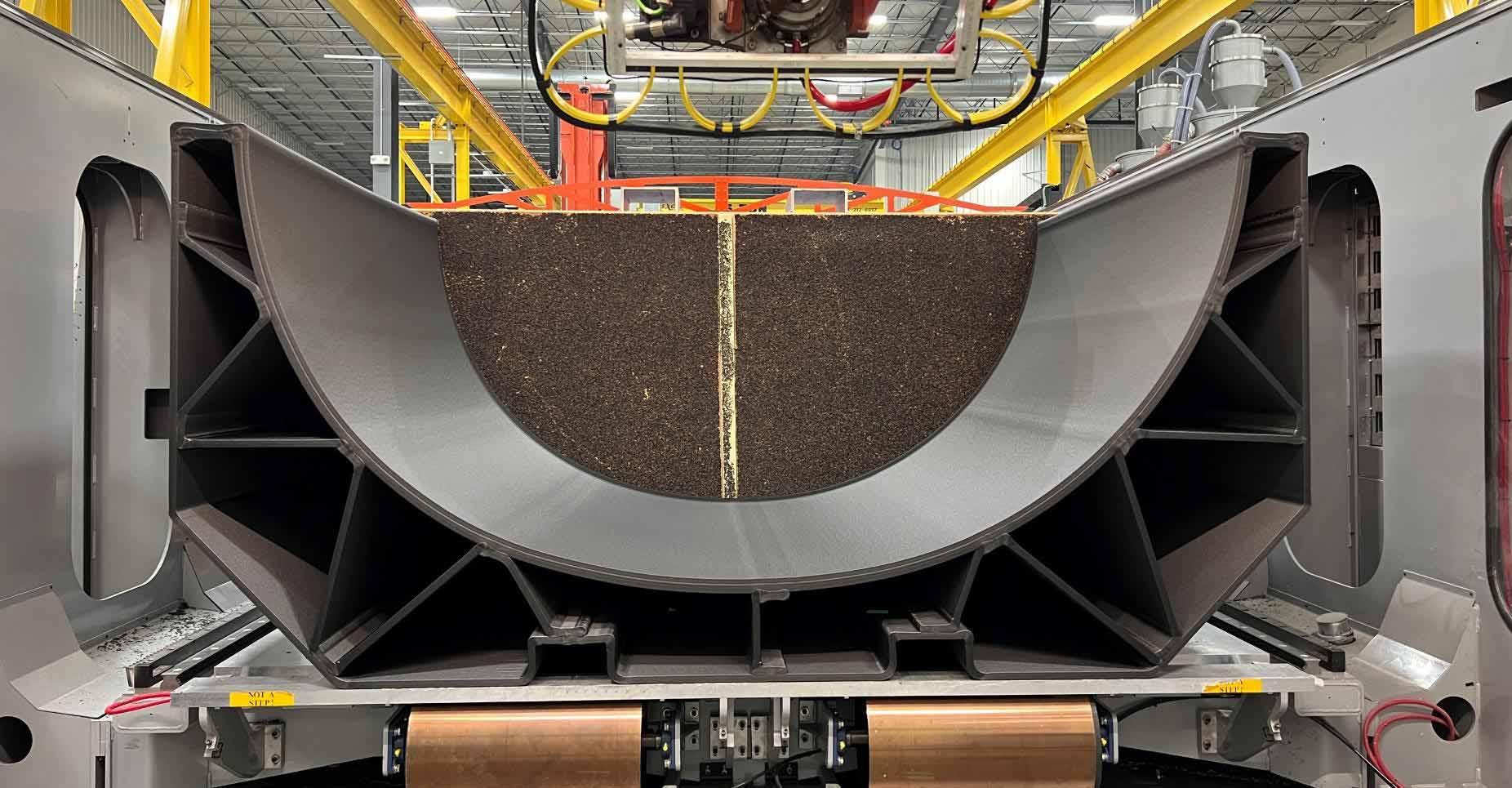

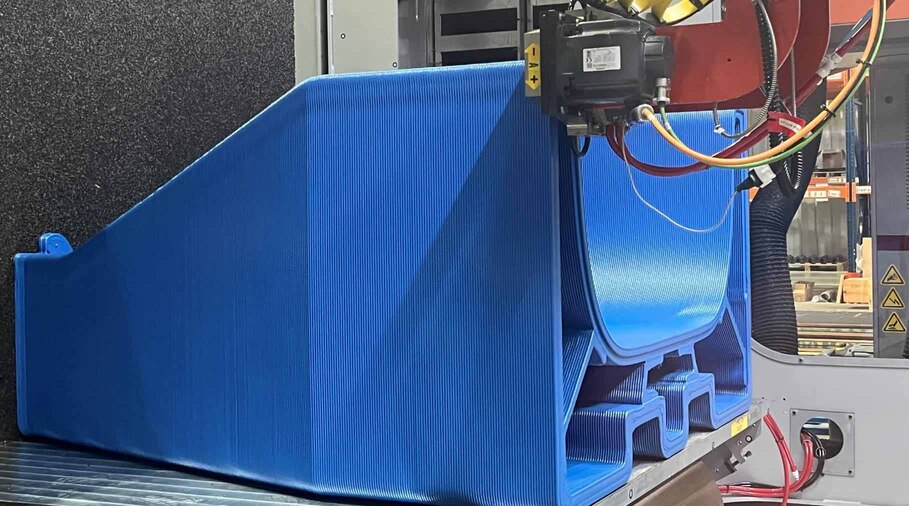

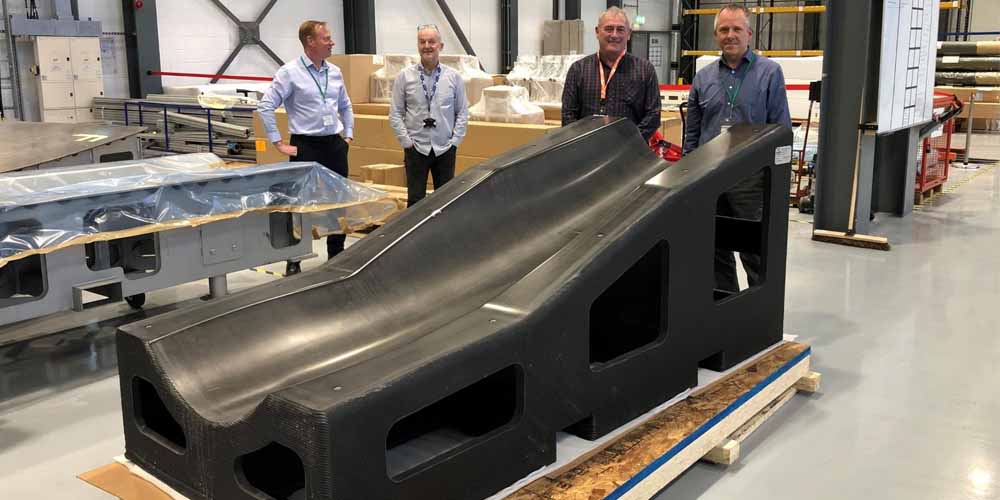

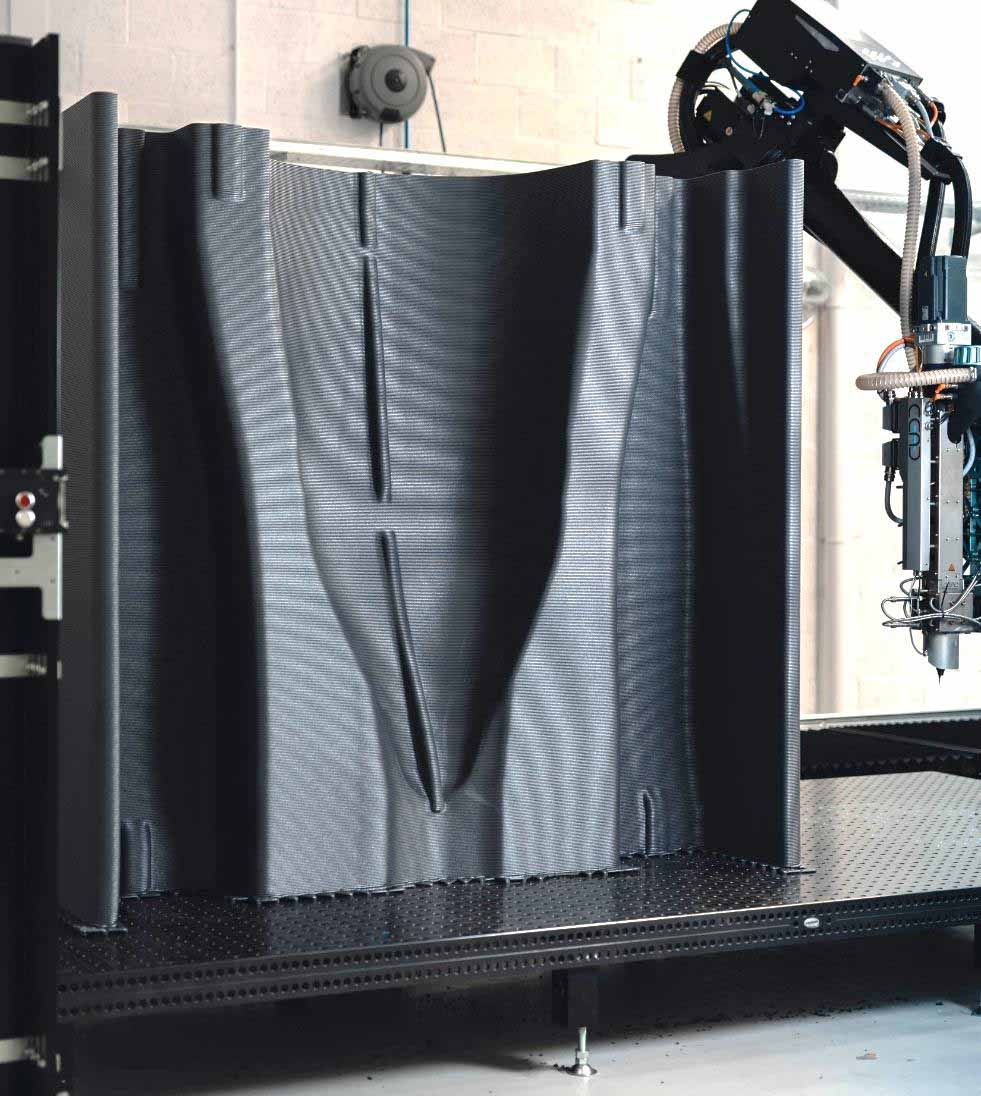

Large and Lightweight AFP Mould

Large and lightweight AFP mould with four-piece tool design with 2 removable details room temperature for transfer to a secondary cure tool. Designed and built at Airtech’s Center of Innovation in Tennessee. Airtech’s Dahltram® C-250CF printed on a Thermwood LSAM with over 100 tool paths per half. Approximately 4,3m x 2m (14ft wide x 6ft tall).

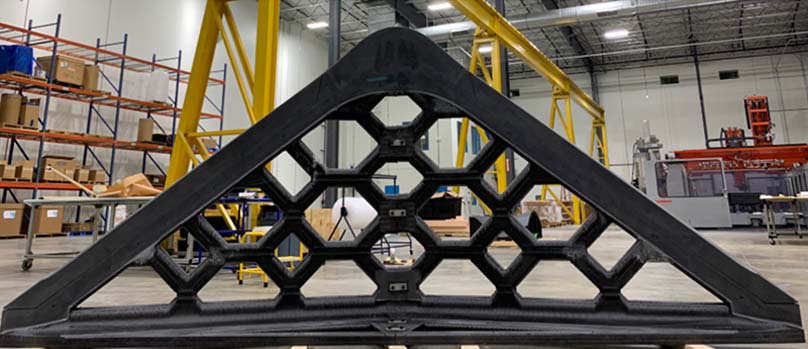

ForzeHydrogen Racing Mould

- Design by Forze

- Printed on CEAD Flexbot Industry S25 + DFC

- Printing time: 44 hours

- Dimensions: 2000 x 800x 2000 mm

- Material: Dahltram® T-100GF (Recycled Co-polyester / Glass Fiber)